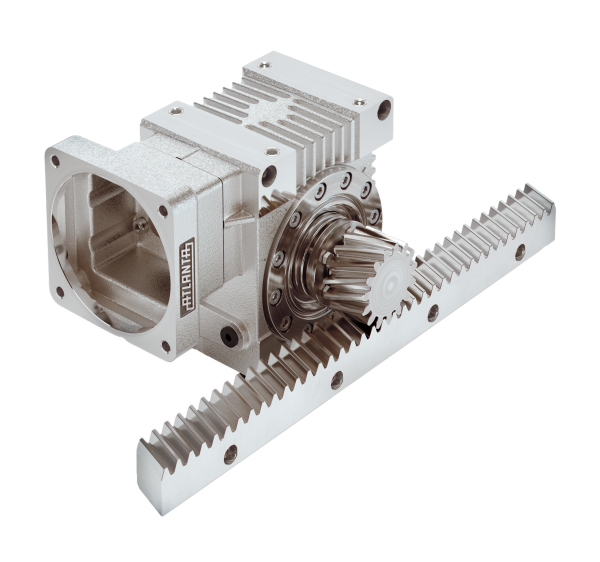

Rack And Pinion Drive System

Rack and pinion drive system. When your vehicles rack and pinion goes out youre going to lose control of the steering system. How a rack and pinion drive system works. This rack moves up and down and drives the inner lever of the flapping wing.

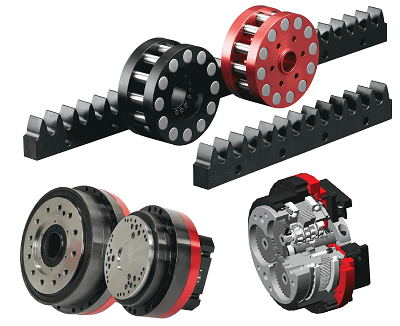

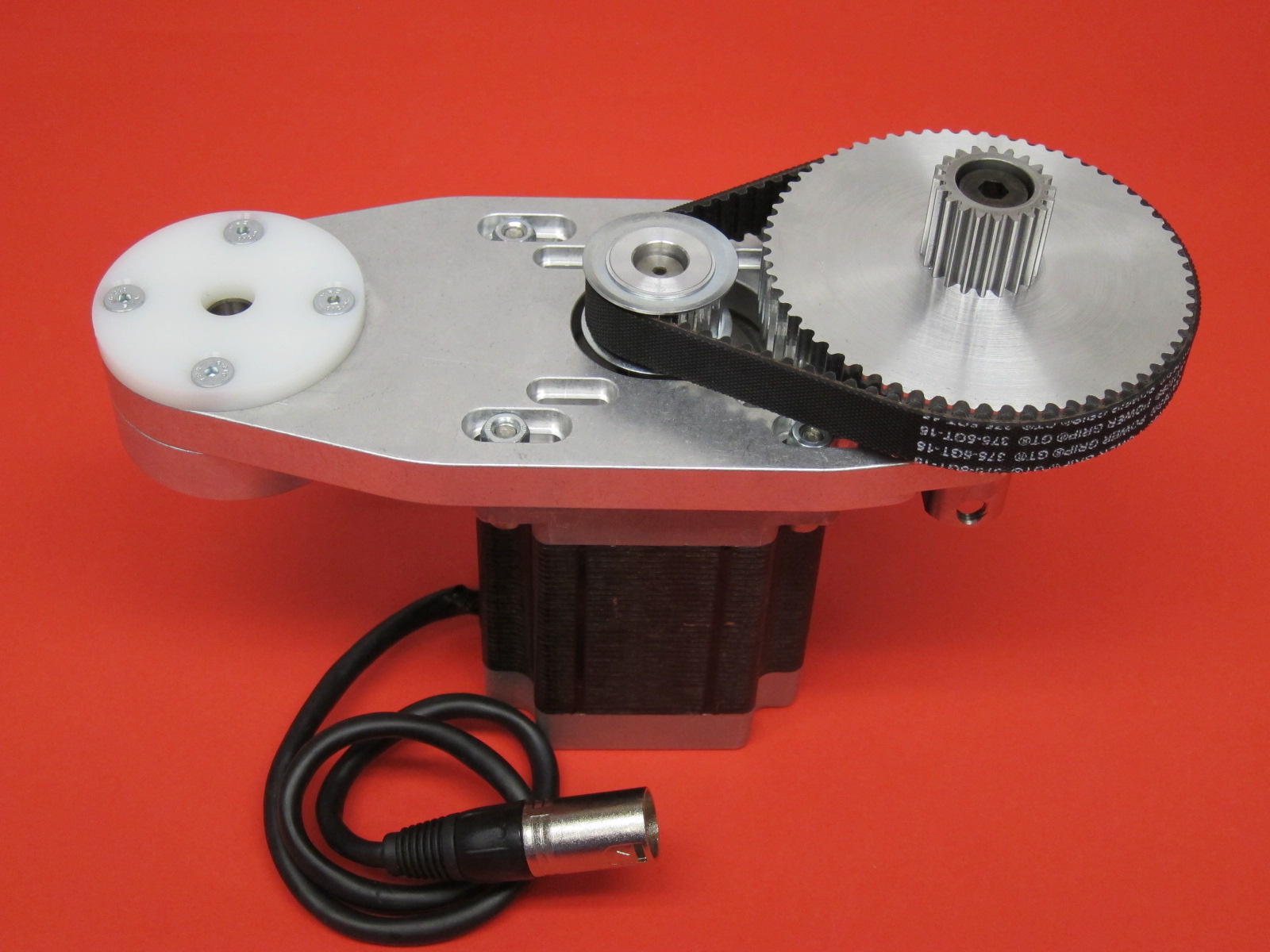

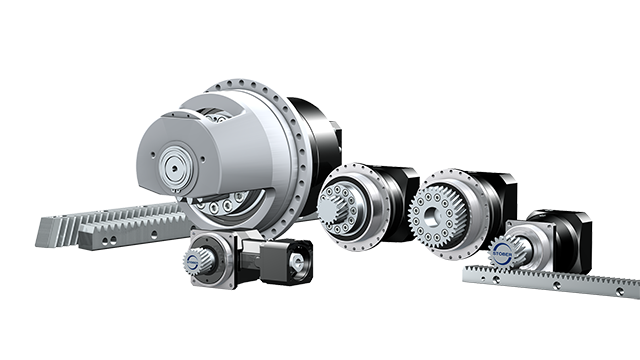

First the power flight must be switched on. By selecting the complete drive system all at once a system can be optimized for the servo motor while achieving the desired accuracy and motion at the rack pinion. This system consists of a standard range of straight spur circumferential pitch and helical racks and pinions.

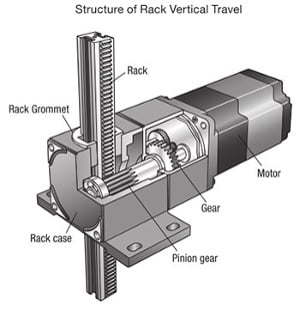

There was used a pin rack with a pitch of 6 mm. As the name suggests there are two key components to a rack and pinion drive system the rack and the pinion. Animation of the rack and pinion system.

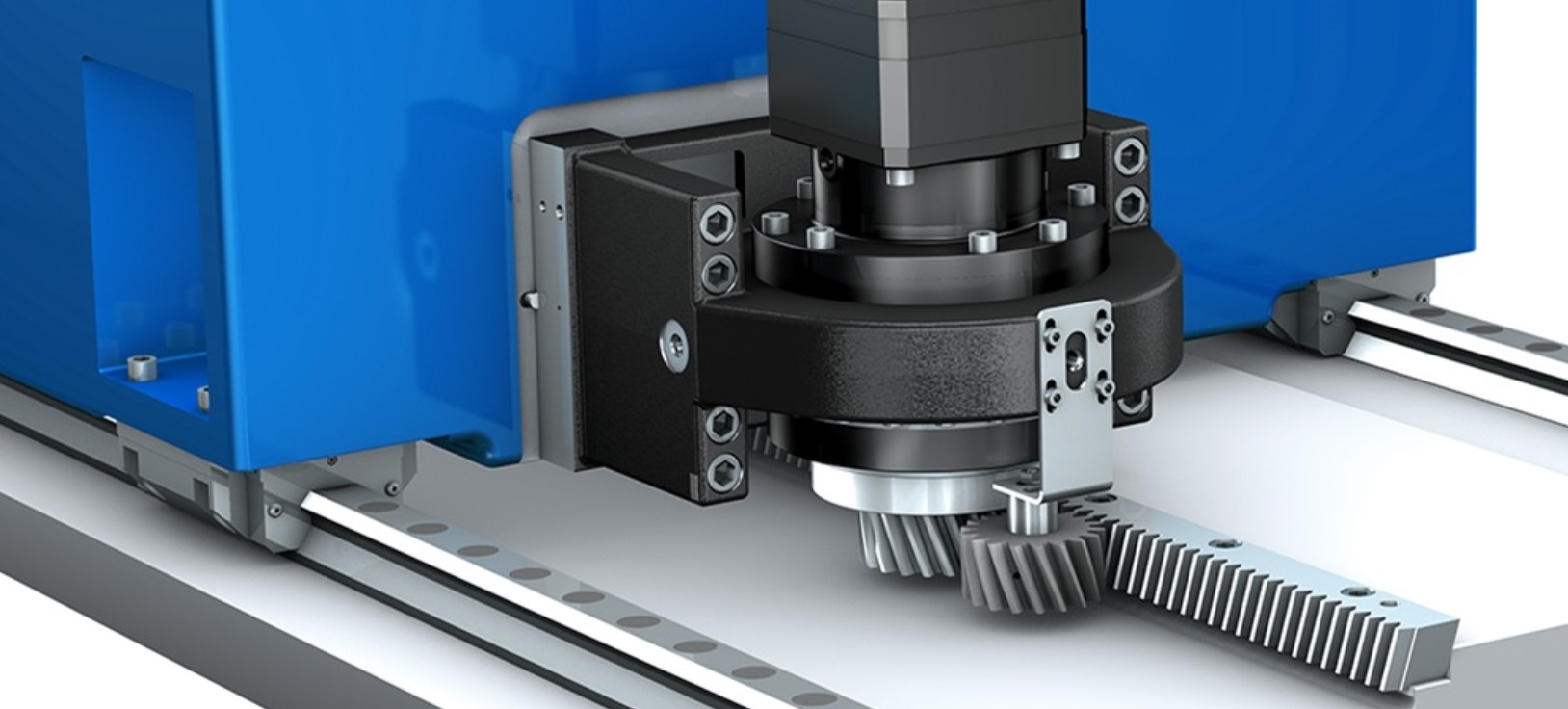

Keywords Manual manufacturing of rack and pinionvariable ackermann anglesgeometry selection. Since the pinion injects the lubricant into the mesh as it rotates across the gear rack the pitch of the rack must be the same as the module of the pinion and in the case of helical rack and pinions the rack and pinion must be of the same helix angle and opposite in direction. Racks can be mounted together and are.

A flexible rack 16 able to travel on a curved locus is preferred. The user receives a compact easy-to-use system with process reliability from a single source a system that is precisely tailored to their task. The pinion runs back and forth over the rack in fact a gear with an infinite radius.

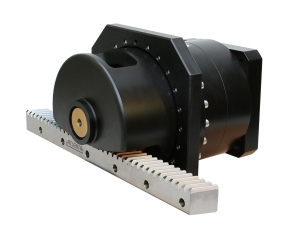

A rack has the property that it can be infinitely long and the accuracy when assembled correctly does not decrease. A rack and pinion drive system is means that there is a rack that is bolted onto the sides of the machines and pinion or coggear that meshes with the rack. Below youre going to delve into this question deeper and learn more about your vehicles rack and pinion system.

We offer a comprehensive lineup of rack and pinion drive systems with exceptional accuracy system rigidity feed forces torque density and efficiency. A drive for a tracked door which utilises a drive pinion 10 which engages a tracked rack 16 that in turn moves the door as it is moved track-wise under the action of the pinion.

The rack is a set of teeth that bolts onto the side of the frame of the CNC machine.

Animation of the rack and pinion system. A flexible rack 16 able to travel on a curved locus is preferred. This rack moves up and down and drives the inner lever of the flapping wing. As the name suggests there are two key components to a rack and pinion drive system the rack and the pinion. A rack has the property that it can be infinitely long and the accuracy when assembled correctly does not decrease. In addition to gearboxes WITTENSTEIN alpha also offers system components such as pinions and racks for your ideal drive system. The rack and pinion in this system are lubricated as the lubricant is dispered by the pinion. A flexible rack able to travel on a curved locus is preferred. First the power flight must be switched on.

Corresponding chain drives are used at model cars. 30 years of experience in the fields of gearbox construction toothing technology and the design of complete drive systems go into our rack and pinion systems. The user receives a compact easy-to-use system with process reliability from a single source a system that is precisely tailored to their task. Drive specialist STOBER offers four different series of rack and pinion drives that can be directly attached to the synchronous servo motors of the EZ series in all sizes. The pinion runs back and forth over the rack in fact a gear with an infinite radius. As the pinion turns the machine moves. There was used a pin rack with a pitch of 6 mm.

Post a Comment for "Rack And Pinion Drive System"